With the rapid development of electrified railway, the manufacture of electric locomotives is also developing towards the direction of heavy haul and high speed traction, which indirectly emphasizes the importance of safety and stability of electric locomotives. As a locomotive brake control device, the brake controller is undoubtedly a very important part of the locomotive electrification control system, which directly relates to the safety and stability of locomotive operation. Brake controller is generally divided into electro-pneumatic brake controller and single brake controller. It is a control device used by drivers to control the brake or mitigation of the whole train. Its control form is the combination of circuit control and pneumatic control. The control circuit is used to indirectly control the opening or closing of the pneumatic valve, so that the wind circuit can be opened or cut off. The purpose of air filling mitigation or exhaust braking of existing trains.

The integrated locomotive brake and ECP brake controller located on the front locomotive is used to perform braking action on all locomotives in a manner related to the braking action applied on the ECP freight car. In the front locomotive, a data interface can be established between the end unit and the brake controller. The head-end unit can transmit signals to each ECP freight car electrically to execute the braking command. The integrated brake controller may include a CPU as part of the brake controller or head unit, which can be programmed to provide and apply on locomotives to ECP freight cars.

The braking action is related to the braking action. Our company provides reliable power supply solutions for locomotive brake controller.

KRS5K600-230 converts the DC 600V supplied by the train into DC230V with stable accuracy up to 0.5%, which is provided to the brake controller. It has reliable working performance and sufficient anti-jamming ability.

1) Input voltage range: DC500V-DC700V;

2) working environment temperature -40- 85C

3) Excellent heat dissipation design, high reliability;

4) Built-in EMC protection circuit, filter circuit and communication expansion function;

5) Protection level IP65, safe and reliable bottom of hoisting truck

6) DC power supply CAN bus communication function, through the control board to set the voltage and current value of the power supply;

7) To meet the requirements of vibration and shock in GB/T 25119, EN50155, GB/T 17626 and EMC protection;

technical conditions

Main Electrical Conditions

Rated input voltage: DC600V

Input voltage range: DC500V-DC700V

Rated output voltage: DC230V + 0.5%

Rated output power: 5kW

Noise: < 65dB (1 m apart from each other in all directions)

mechanical condition

Inverter weight: <35kg

Inverter protection level: IP65

Conditions of Use

Altitude: less than 2500m

Working ambient temperature: -40 C ~+40 C

Relative humidity: <95% (no condensation)

Cooling mode: natural cooling

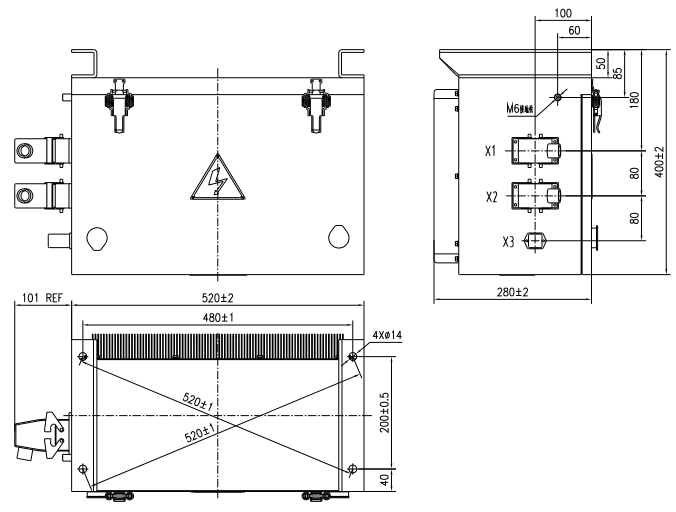

Mechanical dimensions

Dimension: 490 x 300 x 280 mm

Weight: <35kg

The external frame is fixed.